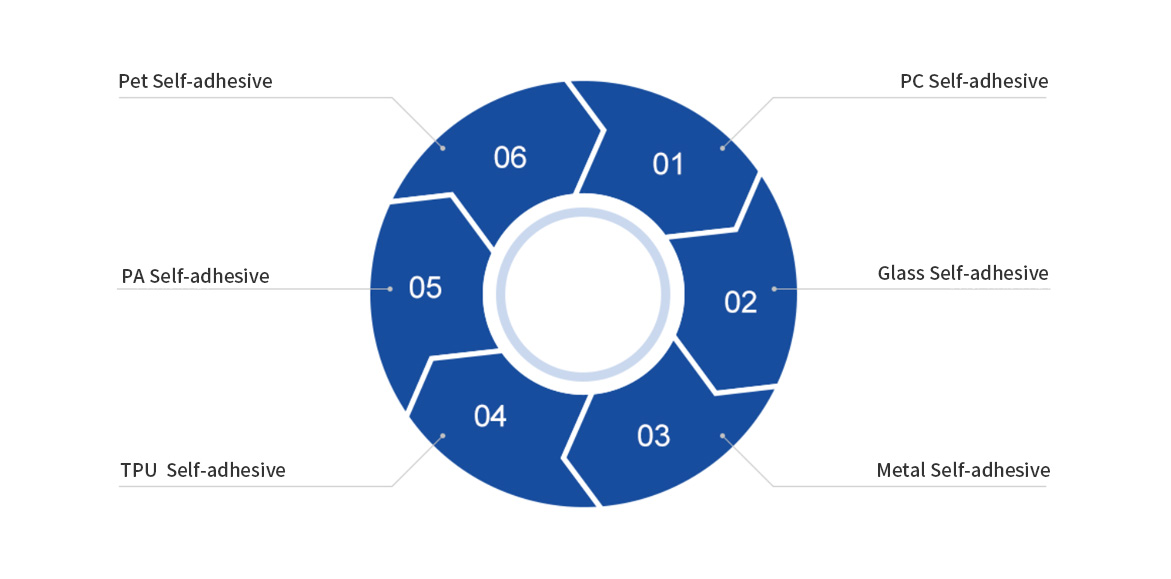

Liquid intrusion is the second leading cause of damage after broken screens, and the global waterproof war of electronic products has given rise to the booming development of liquid self-adhesive silicone. The liquid self-adhesive silicone rubber produced by Beitley truly realizes the free coating agent, greatly reduces the process time and cost, and the perfect product system should deal with the adhesion of different substrates, providing the most solid backing for the waterproof function of electronic products.

BETELY Self-adhesive Liquid Glue

| BETELY Self-adhesive Process | Precipitated silicone Process | General LSR Process |

| Injection molding | Extruding/molding | Injection molding |

| ↓ | Primer | Primer |

| Curing | Curing | |

| Self-adhesive silicone bonds with substrate | Silicone bonds with substrate | Silicone bonds with substrate |

BETELY self-adhesive advantages of liquid glue

1. It has the characteristics of demoulding, easy dyeing, quick curing and good adhesion to different substrates.

2. It has broken foreign technical barriers, and is in the forefront of domestic counterparts, with advantages in cost and quality.

Comparison of Waterproofing Products

| Type | Primer+General LSR | Primer +HSR | BETELY Self-adhesive |

| Quality | 1. Many rough edges; 2. Base coating agent can easily lead to yellowing of adhesive; | 1.Less burrs; 2. Not easy to yellow; | |

| Cost | 1. Many technological processes and high labor cost; 2. The molding temperature is high, the bottom coating needs baking, and the energy consumption is the greatest. | 1. Many technological processes and high labor cost; 2. The base coating needs baking, which consumes a lot of energy. | 1. Simple technological process and low labor cost; 2. Save the cost of primer and baking energy. |

| Production Efficiency | The production efficiency is very low | High production efficiency: because the colloidal mixing, manual weighing, manual cutting and other procedures are eliminated. | The production efficiency is more than 20 times that of “base coating agent + ordinary liquid glue” :(take the mobile phone case covered by silicone as an example). |

| Technological Requirements | It is difficult to produce some products with complicated technology, especially the soft and hard material embedded and the silica gel enveloping and forming. | Although it can produce some products with complicated process, especially the soft and hard material embedded and the silica gel enveloped and formed; But it is difficult to produce the products with high requirements for yellowing and great difficulty for base coating. | Be able to produce more demanding products. |

| Environmental Impact | The base coating agent is usually solvent-based, which affects the working environment of the production workshop. | Does not affect the working environment, is conducive to the physical and mental health of workers and work attitude. | |